project

This project explores the possibilities of galvanic etching on metal plates and its use for matrice generation in artistic printing using electrographic and electroplating techniques. The project is, in turn, a part of the search for solutions to non-toxic engraving methods that aim to give artists a simple, highly creative, and health-wise safe and low cost solution to copper and zinc plate etching via electricity in electrolytic baths and through direct galvanic action without immersion. This system not only facilitates etching or removal of material, but also addition and coating of metals, thus giving rise to a multitude of artistic applications. “Application of electrolysis and electroplating in Fine Arts” is the last project completed. A new publication entitled “Anode-Cathode. Electrolysis and Galvanography. The Chemical Memory Sculpted by Electrons” gathers the conclusions and scientific achievements of this project. Funded in its first stage by the Regional Ministry of Innovation, Development and Industry of the Xunta de Galicia during the 2009-2012 period (under grants for Fundamental Research of the INCITE plan), it has continuity with the project “Industry applications for a new contemporary graphic art. New technologies for multiple imaging, non-toxic engraving and sustainability” of the 2008-2011 National R&D&I Plan of the Ministry of Science and Innovation.

Within the triple approach that articulates the research carried out by the dx5 – digital & graphic art_research group (theoretical-conceptual, artistic-practical and scientific-technical), this project is part of the research lines “From carbon printing to light engraving; Electricity and image generation” and “Sustainability systems and renewable energy applied to contemporary art”, which, in an overall manner, concentrate the different scientific-technical initiatives carried out by the dx5 group in recent years.

Among the main objectives of the different research projects of the dx5 group is the complete abandonment of unhealthy conditions caused by traditional bite and etching techniques with acids and chemical mordants. The non-toxic engraving alternatives developed and refined by the dx5 group circumvent the subsequent recycling process of highly hazardous waste and the difficult and costly sanitation, in a paradigm shift towards electrolysis and galvanography, by using safer methods and systems with no recycling, where electrolytes are not depleted in the process and there is no need to replace them.

Specific objectives:

Optimise electrolytic and galvanic action systems for use in Graphic Arts studios for etching and coatings in Fine Arts, as well as for multidisciplinary production of works of art.

Improve metal plate coating and protection systems and determine the best electrolytes in terms of sustainability, non-mass production price and affordability for artists and industrial sectors.

Generate plate etching methods with systems that use electricity as mordant. Implement and improve materials available in the market for production of contemporary graphic artwork.

Study and improve galvanic action coating techniques for use in artistic practice in contemporary works of art.

Undertake further research into contemporary non-toxic engraving techniques.

Generate a cheap, fast and efficient alternative to conventional acid and salt mordant methods, as an option to replace traditional more polluting and unsafe techniques.

Combine with other current non-toxic techniques.

Perfect plastic graphic artwork results by opening up new technical possibilities for artists thanks to new more precise procedures.

Research implementation:

The objective of this research project is to focus on electrolysis and galvanic action aspects and applications, intended for use in Graphic Arts studios and mainly for engraving and coatings in Fine Arts.

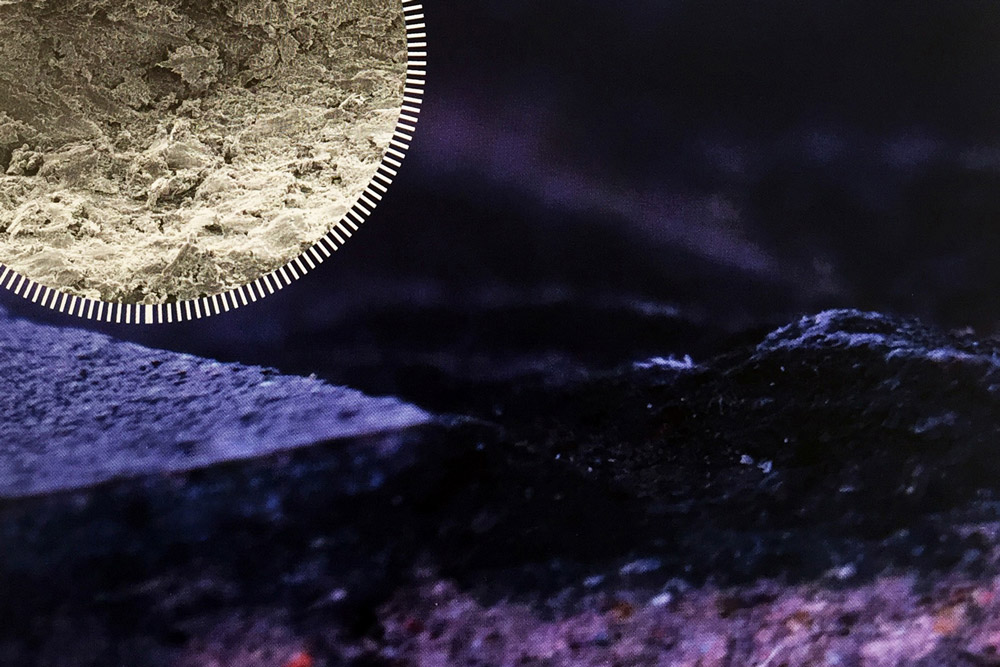

The project aims to delve deep, into the possibilities of galvanic etching on metal plates. This system not only permits etching or removal of material, but also addition and coating of metals, which facilitate a multitude of artistic applications.

Within the specific field of Fine Arts, the implementation and improvement of resources offered by this technology enables us to achieve an effective clean and warm bite that is equal to or better than current alternatives. Its main advantages include physical control, high accuracy in finishes and use of already available materials in the circuit board industry, as well as use of conventional metal plates, including copper, zinc, aluminium or stainless steel. Moreover, it is primarily a highly versatile technique that permits coating of any material such as synthetic fibres, paper, leather, processed fabrics, etc., so that they can be used in artistic practice in current works of art. The optimisation of this industrial technique provides a cheap, fast and efficient alternative to conventional bite methods with acids and salts, especially in combination with other recent non-toxic techniques such as photopolymers, laser ablation, vinyl coatings and digital screen printing.

Key benefits of this procedure include:

-Clean electrolytic corrosion bite that is perpendicular to the plate surface, a phenomenon that provides clean and bright lines. Thus, the bite does not etch the metal below the varnish cap or perforate varnish edges, as is the case with some traditional techniques. The etched lines do not tend to merge, break or cause unpleasant bald areas. The metal structure creates a rough surface at the bottom of the etches which facilitates retention of ink on the widest lines.

-The amount of dissolved metal ions does not change; hence, the electrolyte bath is reusable. This balance and stability of the solution allows us to calculate bite times more accurately than in the case of acids.

-Zinc plates with electrolytic residues can be washed directly under running water in basins because the wash is harmless to plant protection systems and aquifers. This is not the case with plates containing traces of copper sulphate. We will continue research into this recycling point until we reach an optimum level and achieve the right zero contamination conclusions.